After 2 months of building time the moment had come, to print my first printed part.

The strenght is there, or at least it feels like a strong printed part. I am still working on “oozing” and a few other improvements.

I also printed the large gear. This took about 5hrs to print!! That is the speed you get I guess when using threaded rods and not belts.

I am now using slic3r to slice my stl files and I like it a lot. It is fast and I feel I am getting more control of my prints without too many things to tweak. I have eliminated “oozing”” by 99% and the Lift feature is fantastic.

I have printed several parts now, and they are strong and there is no need for any cleaning up. This is thanks to the elimination of “oozing” and the lift setting in slic3r.

I have printed some pulleys for my steppers. These are for a 9mm wide belt (GT2), 2mm toth spacing. Came out very good. It is going to be interesting and see if they will work ok, or if I need to by some metal ones. They have a perfect fit on the belt but I have no experience with wear and tear in regards to plastic pulleys. I also made some idlers for 608 bearings. These are not smooth ones for twisted belts. They have got teeth or grooves which seems to fit perfectly on the belt.

The strenght in these parts are very good.

I love these parts and can’t wait to start using them to build my next printer.

01/04/2012: I have just printed a few new parts with my new hotend design (Jan’s HotEnd MK-II) To bunnies was just a test print for some new colours.

The ball mechanism that controls the water filling in my toilet cistern broke the other day…..how fortunate to have a 3D-printer hey! Measured up the broken part, put it into 123D, sent it to the printer, went to work. When I got home it was there waiting for me…..saved me $20 (I think!) 🙂 (it’s the black part)

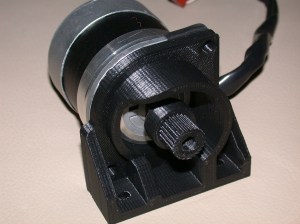

Just finished printing a new bracket for a stepper motor. Very strong and the finish is very nice coming from a printer like this.

===========================

Printed on my new 3DbLue printer:

Did you know that NASA has got some wonderful models that you can download and print?

They are not all easy prints but they look fantastic!

==========================

Cheers

=======================

Excellent site with all the details covered. I like your uncomplicated solutions, with limited tools your achievements are superb. Well done.

Thanks Dennis for you positive comments. Glad you liked my site/blog.

Regards

Jan

Great Blog page man! I owuld love to see more info on how you dialed in the quality of your prints.

Cute colorful bunnies by the way 🙂

Hi and thank you Adam,

Yes I know, there are several items I would like to add, and hopefully I get the time. I have to be careful as well as I am not an expert on this subject and would not like to give out wrong information. Most if not all the info I got from the reprap forum. It has an abundance of information. Most of it does not directly apply to my printer, but the principles do. I would like to add some info on my heatblock and update my heatbed page as well. I really started this just to keep a log of what I was doing, but you know sometimes things get out of hand… 🙂

The bunnies was just a test print to see how the colour samples turned out….very nice colour I thought. We are very lucky to have a manufacturer right here in our backyard, Lybina.

The bunnie ears are probably the smallest piece I have printed and it looks like I need a cooling fan to print small items like that.

Though, I just had a thought, I think maybe the most important thing to achieve decent prints would be to have a reliable good extruder, a reliable good hotend, good quality filament and calibration done. If you don’t have ALL these right, frustration wins and your hobby is dead, as no matter what you tweak you will never get there. But this is also on the forum.

All the best

Regards

Jan